Batteries

In the Batteries step, you can define the various types of batteries available for use. Each battery type has configurable properties related to charging and efficiency.

Battery Swap Time

The battery swap time refers to the duration required to replace battery packs. This input can be stochastic; for more information, refer to the Probability section.

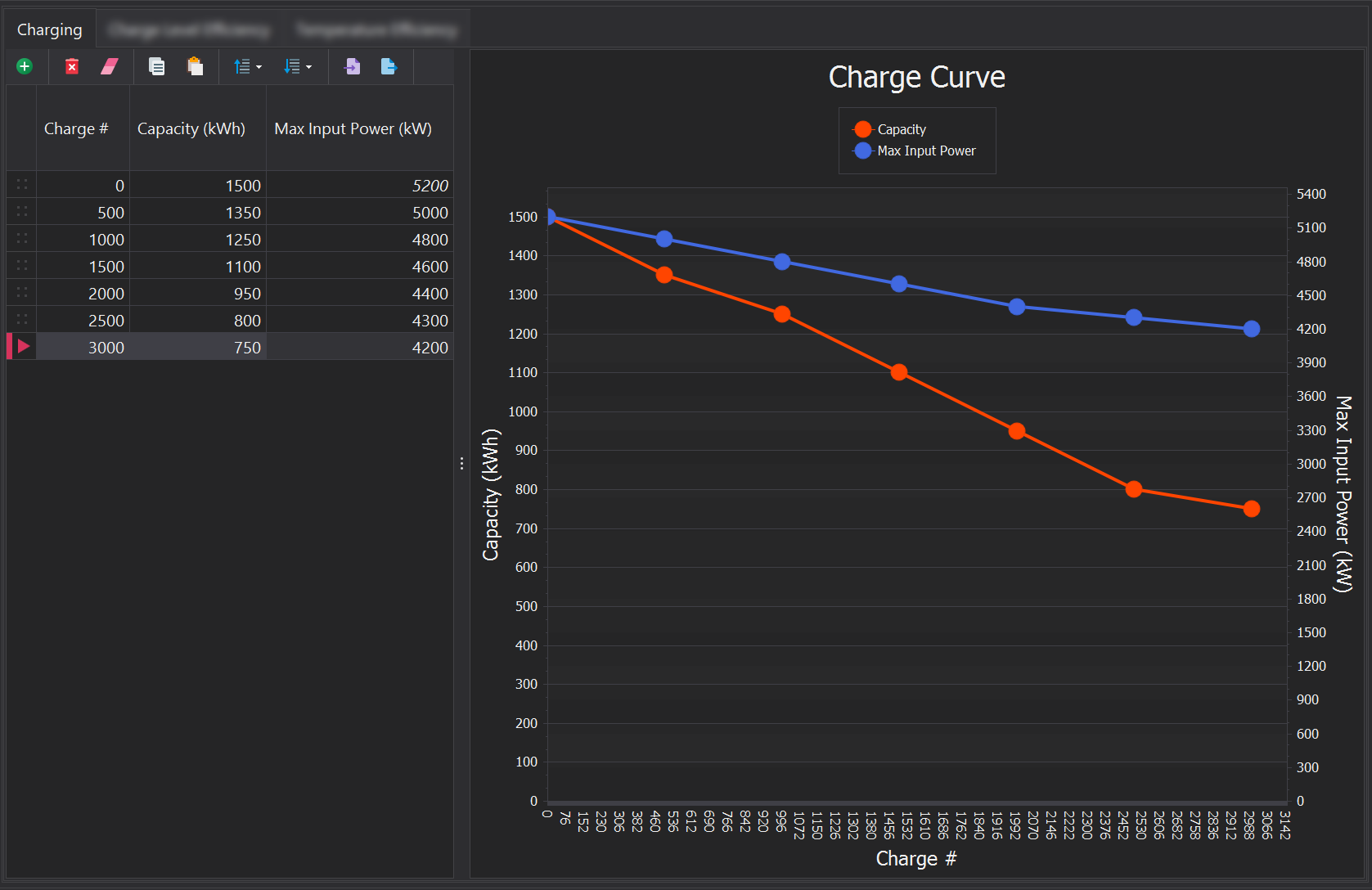

Charging

Battery performance often degrades over time due to charging cycles. As this degradation occurs, the battery loses capacity and may not accept the same amount of power as it did when new. To model this deterioration, you can specify the battery's performance after a certain number of charges.

Charge table entires are managed through the toolbar located at the top. More information on the functions within the toolbar can be found in the Common User Controls page. Each entry must have the following properties specified:

| Input | Description |

|---|---|

| Charge Number | A specific point in the battery's lifecycle where known values of degradation are established. When the battery charge number reaches this point, the battery's capacity and maximum input power are adjusted accordingly. |

| Capacity (kW) | The batteries energy storage capacity at the specified charge number. |

| Max Input Power (kW) | The maximum power the battery can accept during charging at the specified charge number. |

Values for capacity and maximum input power will be interpolated for charge numbers that fall between specified values

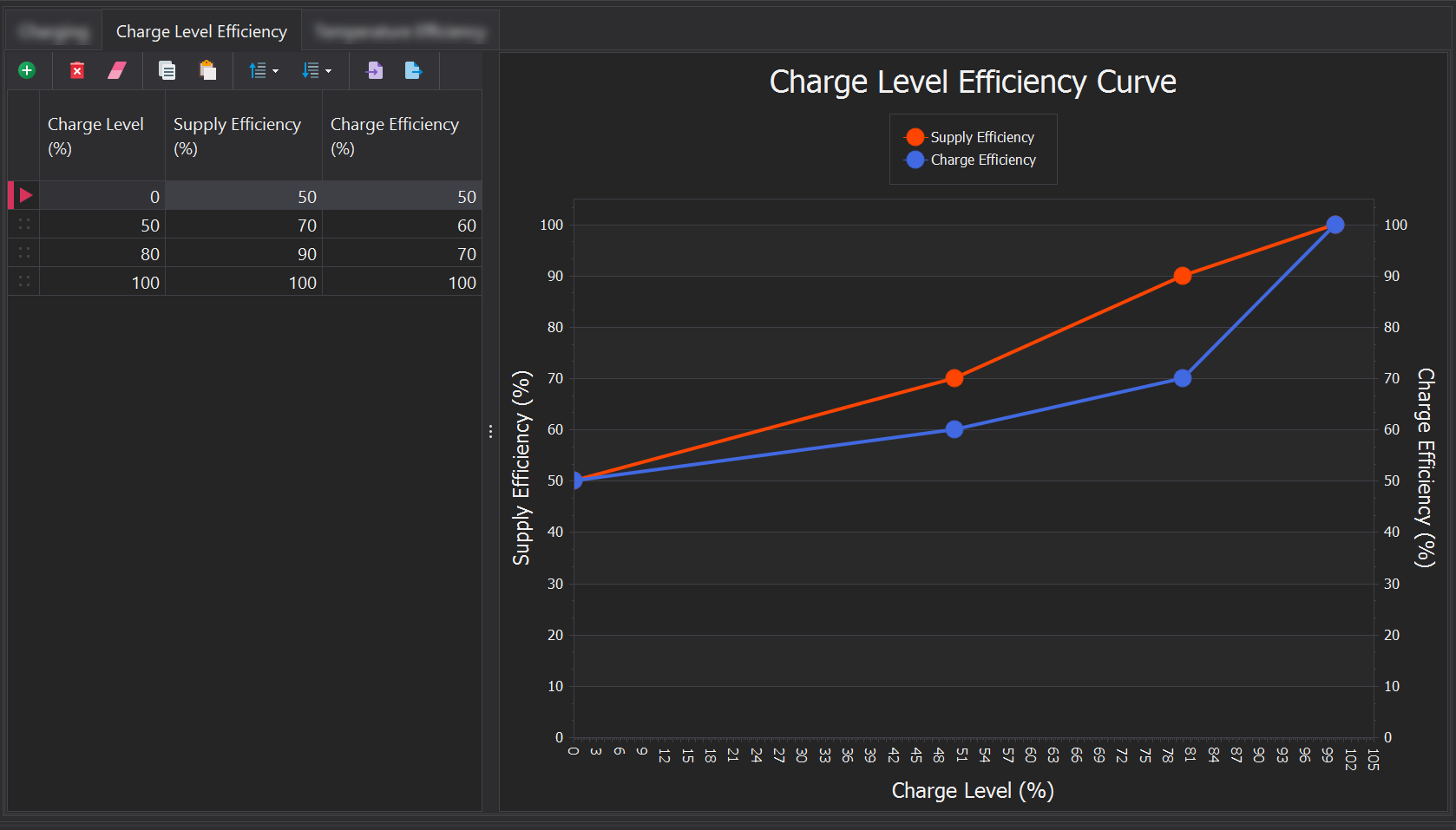

Charge Level Efficiency

Charge Level Efficiency deals with how efficiently energy flows in and out of the battery system at different states of charge (SoC).

Charge Level Efficiency table entires are managed through the toolbar located at the top. More information on the functions within the toolbar can be found in the Common User Controls page. Each entry must have the following properties specified:

Charge Level

The state of charge (SoC) of the battery, showing how much energy is available in the battery at a given time in percentage. The charge level percentage is relative to the batteries capacity for that charge, so if the capacity of the battery has reduced after some number of charges then 100% charge is 100% of that reduced capacity.

Supply Efficiency

This refers to the efficiency of delivering energy from the battery to the wires, essentially representing how well the energy stored in the battery is converted into mechanical power. Energy losses during this process could occur due to inefficiencies in the drivetrain, motor, or other electrical components. High supply efficiency means most of the battery's stored energy is being effectively used for propulsion. There is another efficiency factor for how this wire energy is converted into mechanical work (kinetic energy and gravitational potential) and that factor is implicit in the trucks force & power curves.

Charging Efficiency

This measures how efficiently the battery system can store energy during charging. Not all the energy supplied by the charger is converted into stored energy due to losses (e.g., heat generated during charging). Charging efficiency reflects the percentage of incoming energy that is successfully stored in the battery. You can also use this to stagger charging. Charging a battery is typically not linear and can vary during different phases of the charging cycle. You can use the charging efficiency to model this behaviour.

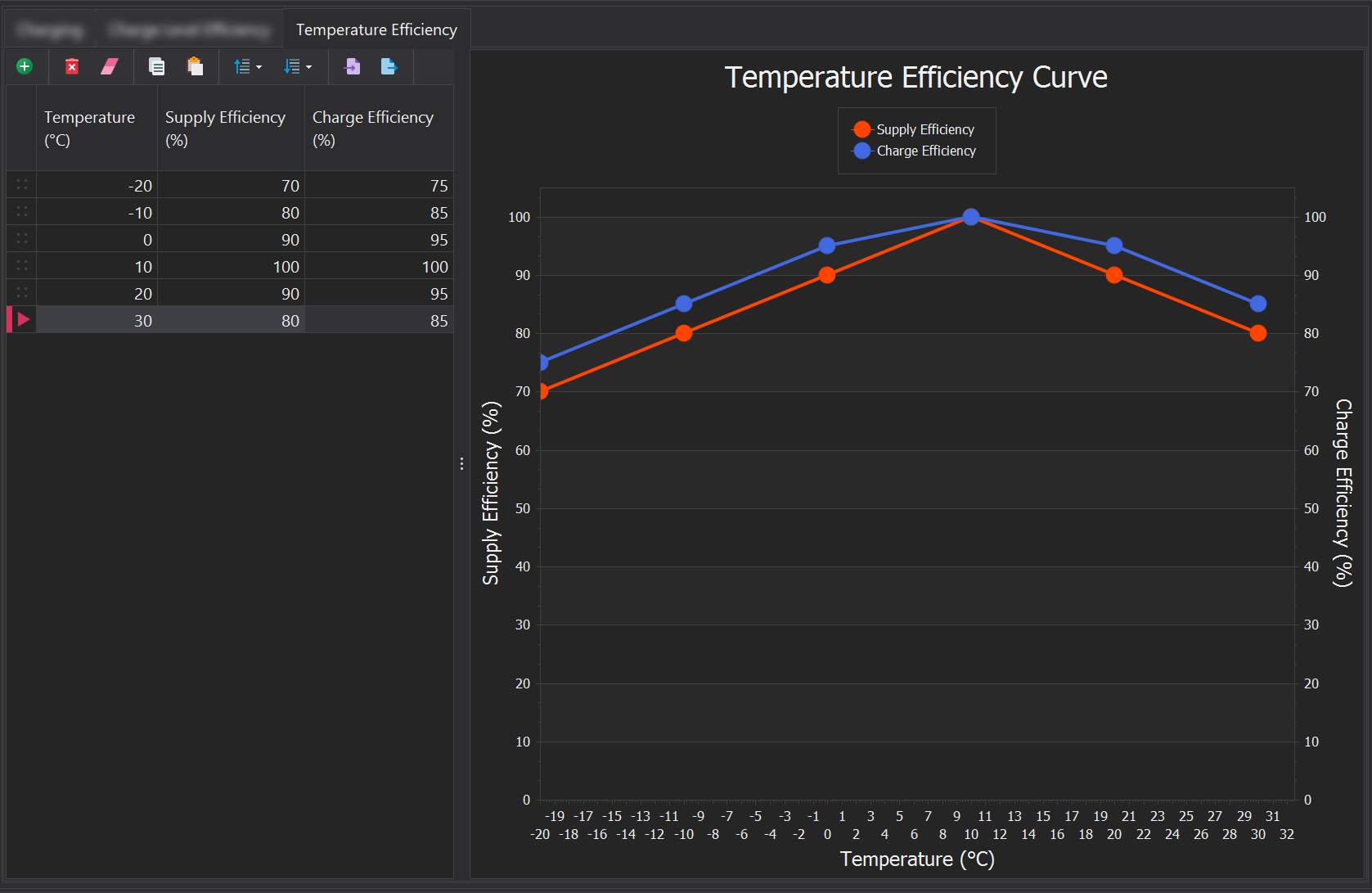

Temperature Efficiency

Temperature Efficiency deals with how efficiently energy flows in and out of the battery system at different temperatures.

Temperature Efficiency table entires are managed through the toolbar located at the top. More information on the functions within the toolbar can be found in the Common User Controls page. Each entry must have the following properties specified:

Temperature

The ambient temperature which known changes in supply and charging effiency are known.

Supply Efficiency

This refers to the efficiency of delivering energy from the battery to the wires, essentially representing how well the energy stored in the battery is converted into mechanical power. Energy losses during this process could occur due to inefficiencies in the drivetrain, motor, or other electrical components. High supply efficiency means most of the battery's stored energy is being effectively used for propulsion. There is another efficiency factor for how this wire energy is converted into mechanical work (kinetic energy and gravitational potential) and that factor is implicit in the trucks force & power curves.

Charging Efficiency

This measures how efficiently the battery system can store energy during charging. Not all the energy supplied by the charger is converted into stored energy due to losses (e.g., heat generated during charging). Charging efficiency reflects the percentage of incoming energy that is successfully stored in the battery. You can also use this to stagger charging. Charging a battery is typically not linear and can vary during different phases of the charging cycle. You can use the charging efficiency to model this behaviour.